You are here:

Products > Heat Shrink Sleeve > Dual Wall Heat Shrink Tubing > Dual Wall Adhesive-Lined Heat-Shrink…

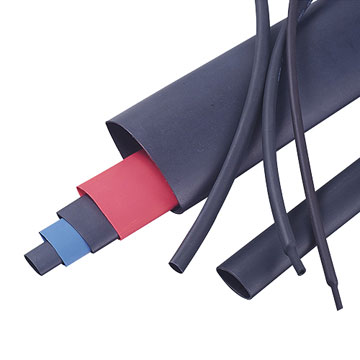

Dual Wall Adhesive-Lined Heat-Shrink Polyolefin Tubing W-1-SB(3X)

Dual Wall Adhesive-Lined Heat-Shrink Polyolefin Tubing

Dual Wall Adhesive-Lined Heat-Shrink Polyolefin Tubing

Adhesive lined heat shrink tubing with environmental sealing capability for a wide variety of electrical applications, including automotive and marine wire harness, wire splices, breakouts, and connector-to-cable transitions.

Features:

- 3:1 shrink ratio

- Longitudinal shrink ratio: =+8%

- Out jacket flame retardant, inner adhesive self-extinguished

- Super sealing against water, moisture or other contaminants

- Continuous operating temperature: -55?~ 125?

- Shrink Temperature:120?

Dimensions

| Size | As supplied | After Recovery | Standard Package | |||

| Inch | mm | Internal Diameter(mm) | Internal Diameter(mm) | Total Wall Thickness(mm) | Adhesive Thickness(mm) |

Spool Length (m/spool) |

| 1/8 | 3.2 | 3.2 | 1.0 | 0.90±0.15 | 0.35±0.10 | 200 |

| 3/16 | 4.8 | 4.8 | 1.6 | 1.00±0.15 | 0.40±0.10 | 100 |

| 1/4 | 6.4 | 6.4 | 2.20 | 1.25±0.15 | 0.45±0.12 | 100 |

| 5/16 | 7.9 | 7.9 | 2.70 | 1.30±0.15 | 0.50±0.12 | 100 |

| 3/8 | 9.5 | 9.5 | 3.20 | 1.40±0.15 | 0.50±0.12 | 50 |

| 1/2 | 12.7 | 12.7 | 4.20 | 1.70±0.15 | 0.50±0.12 | 36.6 |

| 5/8 | 15.0 | 15.0 | 5.20 | 1.80±0.15 | 0.55±0.15 | 30.5 |

| 3/4 | 19.1 | 19.1 | 6.30 | 1.95±0.15 | 0.55±0.15 | 30.5 |

| 1 | 25.4 | 25.4 | 8.50 | 2.05±0.20 | 0.55±0.15 | 30.5 |

| 1-1/4 | 30.0 | 30.0 | 10.20 | 2.20±0.20 | 0.60±0.15 | 24.4 |

| 1-1/2 | 39.0 | 39.0 | 13.50 | 2.50±0.20 | 0.60±0.15 | 18.3 |

| 2 | 50.0 | 50.0 | 17.00 | 2.80±0.25 | 0.70±0.15 | 12.2 |

| 5/2 | 64 | 64 | 21.00 | 3.00±0.25 | 0.70±0.15 | 6.1 |

| 3 | 75 | 75 | 25.00 | 3.00±0.30 | 1.00±0.20 | 1.22 |

| 7/2 | 90 | 90 | 30.00 | 3.00±0.30 | 1.00±0.20 | 1.22 |

| 4 | 100 | 100 | 34.00 | 3.00±0.30 | 1.00±0.20 | 1.22 |

| 5 | 125 | 125 | 42.00 | 3.00±0.30 | 1.00±0.20 | 1.22 |

Technical Data

| Test Item | Test Method | Test Result |

| Tensile Strength(Mpa) | ASTM D2671 | =10.4 |

| Elongation% | ASTM D2671 | =300 |

| Tensile Strength after Aging(Mpa) | UL 224 158×168hr | =7.3 |

| Elongation after Aging% | UL 224 158?×168hr | =200 |

| Dielectric Strength | IEC 243 | = 15 |

| Volume Resistance(O.cm) | ASTM D876 | = 1014O.cm |

Hot Melting Adhesive Property

| Test Item | Test Method | Test Result |

| Water absorption ratio: | ASTM-D570 | <0.2% |

| Softing point | ASTM-E8 | 95? |

| Strength of pearing(PE) | ASTM-D1000 | 120N/25m |

| Strength of pearing(AL) | ASTM-D1000 | 80N/25m |